Description

Product Name : sawl pipe , carbon steel pipes

Size :

Outer Diameter: 355.6mm-2320mm

Wall Thickness: 7-50mm

Length: 5.8m / 6m / 11.8m / 12m / 18m / 32m

Standard :

API 5L PSL1 / PSL2 Gr.A , Gr.B , X42, X46 , X52 , X56 , X60 , X65 ,

X70

ASTM A53 / A252 / A500 / A672 / A691 / A139

EN10025 / EN10210 / EN10219 / EN10217 / EN10208 / EN10297

AS1163 / JIS G3457 / JIS G3101

DIN 17100

Ends : Black ends / Bevelled ends / Plain ends

Surface Treatment : Bare , Black Painting , Varnished , Galvanized

, Anti-corrosion coating , etc .

Application: Used for oil and gas , water transmission ,

engineering , offshore projects .

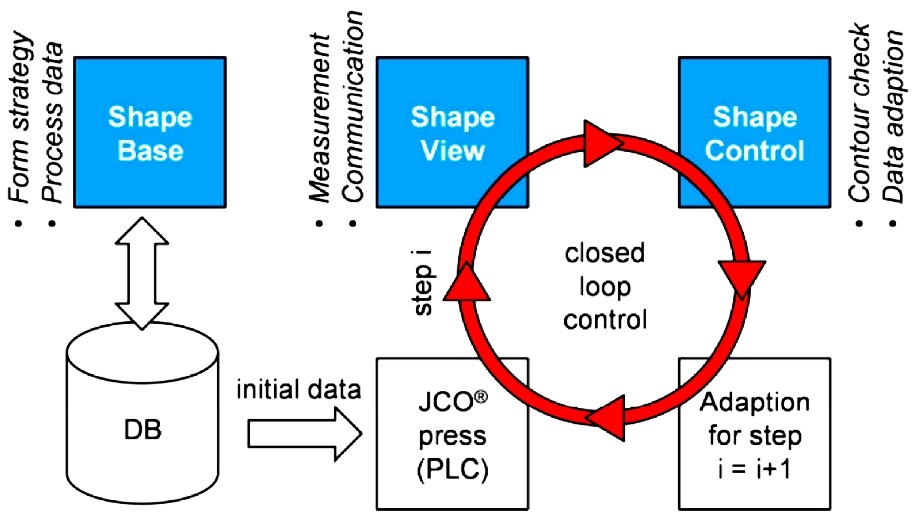

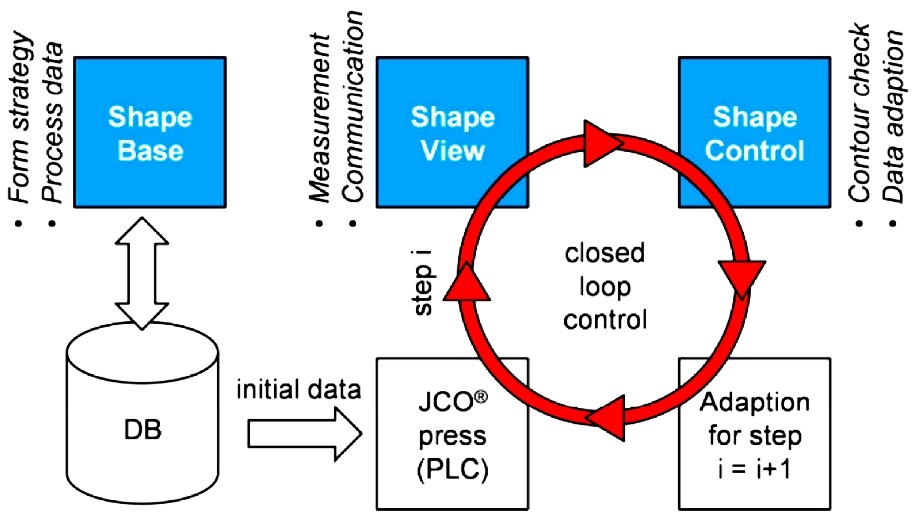

LSAW ( Longitudinally Submerged Arc Welding ) Pipe can be divided

into UOE and JCOE pipe according to its processing methods . LSAW

steel pipe has the characteristics of relatively simple process and

fast continuous production , and has widely used in oil and gas ,

water transmission , engineering , offshore projects .

LSAW pipe used to convey low pressure liquid or high pressure

petroleum or natural gas, and can be also used widely in structural

supports or foundation. The advantage for LSAW type is they could

produce more thick wall thickness of pipes, maximum to 120mm.

Features of LSAW Steel Pipe

- Large diameter

- Thick wall

- High Pressure resistance

- Low-temperature resistance

Tests:

- Chemical Component Analysis

- Mechanical Properties – Elongation, Yield Strength, Ultimate

Tensile Strength

- Technical Properties – DWT Test, Impact Test, Blow Test,

Flattening Test

- X-ray Test

- Exterior Size Inspection

- Hydrostatic Test

- UT Test

| UOE LSAW Pipe |

| Outside Diameter : Φ508mm - 1118mm ( 20"- 44" ) |

| Wall Thickness : 6.0 - 25.4mm 1/4"-1" |

| Quality Standards : API , DNV , ISO , DEP , EN , ASTM , DIN , BS ,

JIS , GB , CSA |

| Length : 9 - 12.3m (30'- 40') |

| Grades : API 5L A-X90 , GB/T9711 L190-L625 |

| JCOE LSAW Pipe |

| Outside Diameter : Φ406mm - 1626mm ( 16" - 64" ) |

| Wall Thickness : 6.0 - 75mm ( 1/4" - 3" ) |

| Quality Standards : API , DNV , ISO , DEP , EN , ASTM , DIN , BS ,

JIS , GB , CSA |

| Length : 3 - 12.5m ( 10'- 41' ) |

| Grades : API 5L A-X100 , GB/T9711 L190-L690 |

Specification

| O.D. | W.T. | Length ( m ) |

| Inch | mm | Min.Yield Strength ( Mpa ) |

| Inch | mm | 245(B) | 290(X42) | 360(X52) | 415(X60) | 450(X65) | 485(X70) | 555(X80) |

| 16 | 406 | 6.0-14.0 | 6.0-13.0 | 6.0-12.0 | 6.0-11.0 | 6.0-10.5 | 6.0-10.0 | 6.0-9.0 | 6.0-12.3 |

| 18 | 457 | 6.0-15.0 | 6.0-14.0 | 6.0-13.0 | 6.0-12.0 | 6.0-11.5 | 6.0-11.0 | 6.0-10.0 | 6.0-12.3 |

| 20 | 508 | 6.0-16.0 | 6.0-15.0 | 6.0-14.0 | 6.0-13.0 | 6.0-12.5 | 6.0-12.0 | 6.0-11.0 | 6.0-12.3 |

| 22 | 559 | 6.0-17.0 | 6.0-16.0 | 6.0-15.0 | 6.0-14.0 | 6.0-13.5 | 6.0-13.0 | 6.0-12.0 | 6.0-12.3 |

| 24 | 610 | 6.0-18.0 | 6.0-17.0 | 6.0-16.0 | 6.0-15.0 | 6.0-14.5 | 6.0-14.0 | 6.0-13.0 | 6.0-12.3 |

| 26 | 660 | 6.0-19.0 | 6.0-18.0 | 6.0-17.0 | 6.0-16.0 | 6.0-15.0 | 6.0-15.0 | 6.0-14.0 | 6.0-12.3 |

| 28 | 711 | 6.0-20.0 | 6.0-19.0 | 6.0-18.0 | 6.0-17.0 | 6.0-16.5 | 6.0-16.0 | 6.0-15.0 | 6.0-12.3 |

| 30 | 762 | 7.0-21.0 | 7.0-20.0 | 7.0-19.0 | 7.0-18.0 | 7.0-17.5 | 7.0-17.0 | 7.0-16.0 | 6.0-12.3 |

| 32 | 813 | 7.0-22.0 | 7.0-21.0 | 7.0-20.0 | 7.0-19.0 | 7.0-18.5 | 7.0-18.0 | 7.0-17.0 | 6.0-12.3 |

| 34 | 864 | 7.0-23.0 | 7.0-22.0 | 7.0-21.0 | 7.0-20.0 | 7.0-19.5 | 7.0-19.0 | 7.0-18.0 | 6.0-12.3 |

| 36 | 914 | 8.0-24.0 | 8.0-23.0 | 8.0-22.0 | 8.0-21.0 | 8.0-20.5 | 8.0-20.0 | 8.0-19.0 | 6.0-12.3 |

| 38 | 965 | 8.0-25.0 | 8.0-24.0 | 8.0-23.0 | 8.0-22.0 | 8.0-21.5 | 8.0-21.0 | 8.0-20.0 | 6.0-12.3 |

| 40 | 1016 | 8.0-26.0 | 8.0-25.0 | 8.0-24.0 | 8.0-23.0 | 8.0-22.5 | 8.0-22.0 | 8.0-21.0 | 6.0-12.3 |

| 42 | 1067 | 8.0-26.0 | 8.0-25.0 | 8.0-24.0 | 8.0-23.0 | 8.0-22.5 | 8.0-22.0 | 8.0-21.0 | 6.0-12.3 |

| 44 | 1118 | 9.0-27.0 | 9.0-26.0 | 9.0-24.5 | 9.0-23.5 | 9.0-22.8 | 9.0-22.0 | 9.0-21.0 | 6.0-12.3 |

| 46 | 1168 | 9.0-27.0 | 9.0-26.0 | 9.0-24.0 | 9.0-23.5 | 9.0-22.8 | 9.0-22.0 | 9.0-21.0 | 6.0-12.3 |

| 48 | 1219 | 9.0-28.0 | 9.0-27.0 | 9.0-25.4 | 9.0-24.0 | 9.0-23.5 | 9.0-23.0 | 9.0-22.0 | 6.0-12.3 |

| 52 | 1321 | 9.0-28.0 | 9.0-27.0 | 9.0-25.4 | 9.0-24.2 | 9.0-23.5 | 9.0-23.0 | 9.0-22.0 | 6.0-12.3 |

| 56 | 1422 | 10.0-29.0 | 10.0-28.0 | 10.0-26.0 | 10.0-24.5 | 10.0-23.8 | 10.0-23.0 | 10.0-22.0 | 6.0-12.3 |

| 60 | 1524 | 10.0-29.0 | 10.0-28.0 | 10.0-26.0 | 10.0-24.5 | 10.0-23.8 | 10.0-23.0 | 10.0-22.0 | 6.0-12.3 |

| 64 | 1626 | 10.0-30.0 | 10.0-29.0 | 10.0-27.0 | 10.0-25.4 | 10.0-24.8 | 10.0-24.0 | 10.0-23.0 | 6.0-12.3 |

| 68 | 1727 | 10.0-30.0 | 10.0-29.0 | 10.0-27.0 | 10.0-25.4 | 10.0-24.8 | 10.0-24.0 | 10.0-23.0 | 6.0-12.3 |

| 72 | 1829 | 10.0-30.0 | 10.0-29.0 | 10.0-27.0 | 10.0-25.4 | 10.0-24.8 | 10.0-24.0 | 10.0-23.0 | 6.0-12.3 |

Standard

| ASTM A53 | Standard Specification for Pipe, Steel, Black and Hot-Dipped,

Zinc-Coated, Welded and Seamless |

| API 5L | Specification for Line Pipe(Two levels PSL 1 and PSL 2 of seamless

and welded steel pipes for use in pipeline transportation systems

in the petroleum and natural gas industries.) |

| A252 | Standard Specification for Welded and Seamless Steel Pipe Piles |

| A500 | Specification for Cold-Formed Welded and Seamless Carbon Steel

Structural Tubing in Rounds and Shapes |

| A139 | Standard Specification for Electric-Fusion (Arc)-Welded Steel Pipe

(NPS 4 and Over) |

| A672 | Specification for Electric-Fusion-Welded Steel Pipe for

High-Pressure Service at Moderate Temperatures |

| A691 | Specification for Carbon and Alloy Steel Pipe,

Electric-Fusion-Welded for High-Pressure Service at High

Temperatures |

Tolerance of Outside Diameter and Wall Thickness of LSAW Steel Pipe

| Types | Standard |

| SY/T5040-2000 | SY/T5037-2000 | SY/T9711.1-1977 | ASTM A252 | AWWA C200-97 | API 5L PSL1 |

| Tube end OD deviation | ±0.5%D | ±0.5%D | -0.79mm~+2.38mm | <±0.1%T | <±0.1%T | ±1.6mm |

| Wall thickness | ±10.0%T | D<508mm, ±12.5%T | -8%T~+19.5%T | <-12.5%T | -8%T~+19.5%T | 5.0mm |

| D>508mm, ±10.0%T | T≥15.0mm, ±1.5mm |

Chemical Composition and Mechanical Properties of LSAW Steel Pipe

| Standard | Grade | Chemical Composition (max)% | Mechanical Properties ( min ) |

| C | Mn | Si | S | P | Yield Strength ( Mpa ) | Tensile Strength ( Mpa ) |

| GB/T700-2006 | A | 0.22 | 1.4 | 0.35 | 0.050 | 0.045 | 235 | 370 |

| B | 0.2 | 1.4 | 0.35 | 0.045 | 0.045 | 235 | 370 |

| C | 0.17 | 1.4 | 0.35 | 0.040 | 0.040 | 235 | 370 |

| D | 0.17 | 1.4 | 0.35 | 0.035 | 0.035 | 235 | 370 |

| GB/T1591-2009 | A | 0.2 | 1.7 | 0.5 | 0.035 | 0.035 | 345 | 470 |

| B | 0.2 | 1.7 | 0.5 | 0.030 | 0.030 | 345 | 470 |

| C | 0.2 | 1.7 | 0.5 | 0.030 | 0.030 | 345 | 470 |

| BS EN10025 | S235JR | 0.17 | 1.4 | - | 0.035 | 0.035 | 235 | 360 |

| S275JR | 0.21 | 1.5 | - | 0.035 | 0.035 | 275 | 410 |

| S355JR | 0.24 | 1.6 | - | 0.035 | 0.035 | 355 | 470 |

| DIN 17100 | ST37-2 | 0.2 | - | - | 0.050 | 0.050 | 225 | 340 |

| ST44-2 | 0.21 | - | - | 0.050 | 0.050 | 265 | 410 |

| ST52-3 | 0.2 | 1.6 | 0.55 | 0.040 | 0.040 | 345 | 490 |

| JIS G3101 | SS400 | - | - | - | 0.050 | 0.050 | 235 | 400 |

| SS490 | - | - | - | 0.050 | 0.050 | 275 | 490 |

| API 5L PSL1 | A | 0.22 | 0.9 | - | 0.03 | 0.03 | 210 | 335 |

| B | 0.26 | 1.2 | - | 0.03 | 0.03 | 245 | 415 |

| X42 | 0.26 | 1.3 | - | 0.03 | 0.03 | 290 | 415 |

| X46 | 0.26 | 1.4 | - | 0.03 | 0.03 | 320 | 435 |

| X52 | 0.26 | 1.4 | - | 0.03 | 0.03 | 360 | 460 |

| X56 | 0.26 | 1.1 | - | 0.03 | 0.03 | 390 | 490 |

| X60 | 0.26 | 1.4 | - | 0.03 | 0.03 | 415 | 520 |

| X65 | 0.26 | 1.45 | - | 0.03 | 0.03 | 450 | 535 |

| X70 | 0.26 | 1.65 | - | 0.03 | 0.03 | 585 | 570 |

Process

The three main forming steps of the UOE LSAW pipe forming process

include : steel plate pre-bending , U forming and O forming . Each

process uses a special forming press to complete the three

processes of steel plate pre-bending , U forming , and O forming in

sequence , so that the steel plate is deformed into a round tube .

After several steps of stamping on the JCO forming machine , first

half of the steel plate is pressed into a "J" shape , and then the

other half of the steel plate is pressed into a "J" shape to form a

"C" shape , and finally an open "O" is formed by pressing from the

middle Type tube blank.

Packing